Limpet Labels UK Ltd,

Russell House,

Abbey Road North,

Wrexham Industrial Estate,

Wrexham,

Wales

L13 9RX

T +44 (0) 1978 664411

E sales@limpetlabels.co.uk

www.limpetlabels.co.uk

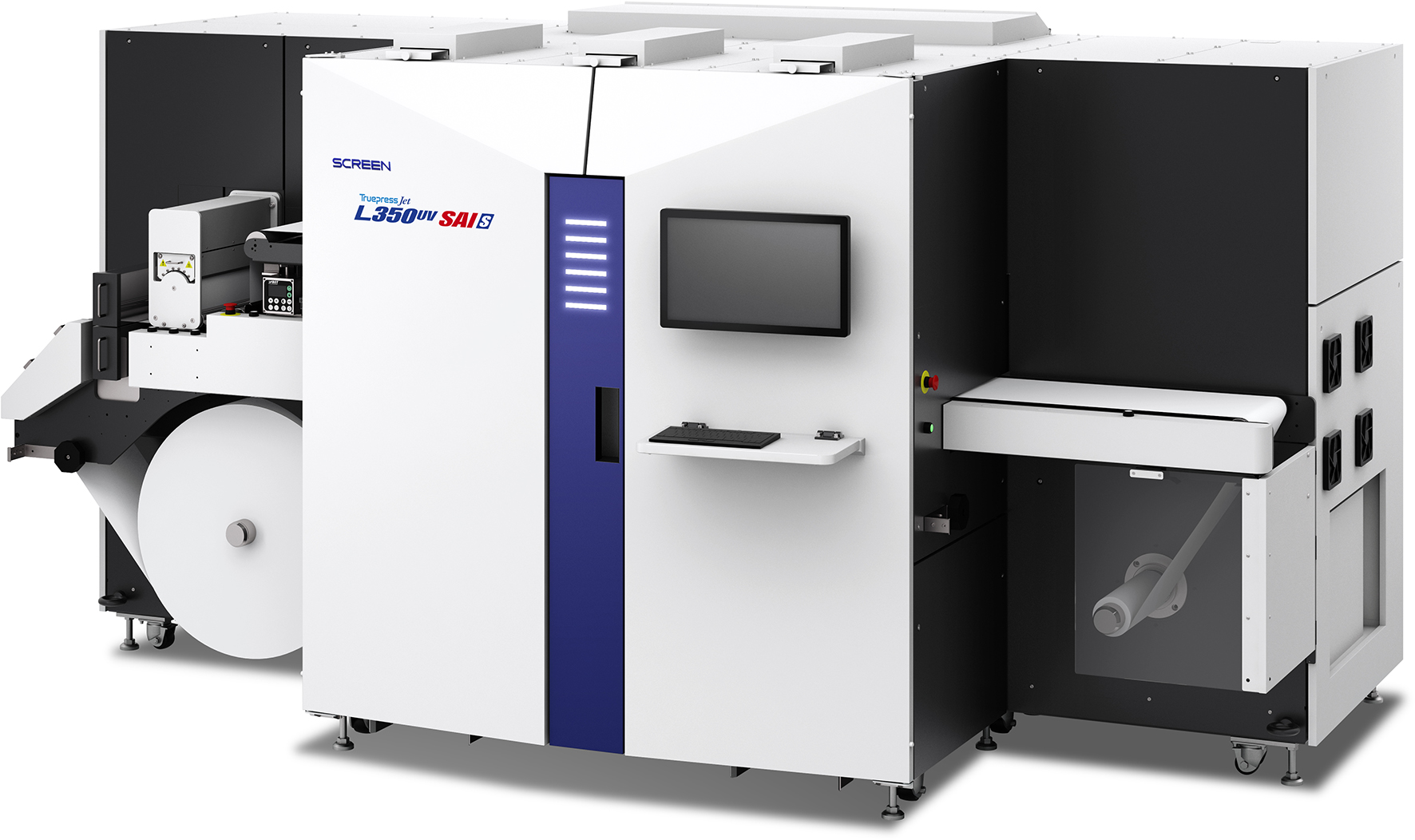

Screen Product:

One Truepress Jet L350UV and a Truepress Jet L350UV+ press

Fast Facts:

- Installation of Screen Truepress Jet L350UV+ in 2018 followed the positive experience of Screen Truepress Jet L350UV press investment in 2014

- Using both Screen presses concurrently increased capacity by over 60% compared to running the Screen Truepress Jet L350UV alongside a toner-based device

- New label applications achievable with the addition of the chilled roller

- Both Screen Truepress Jet L350UV printers are fully integrated with the Esko front-end system

Founded in 1992 in Wrexham, Wales, Limpet Labels is an established producer of high-quality self-adhesive labels. The company primarily produces labels for challenging applications in the industrial, chemical, oil and hygiene markets, where print accuracy and durability are a prerequisite.

In order to meet these stringent demands, Limpet Labels deployed both digital print and flexo technologies. In 2014, the company added a Screen Truepress Jet L350UV to work alongside its existing toner-based and flexo systems. Running at 50 meters per minute, the Truepress Jet L350UV proved so instrumental in the production of consistent high-quality labels, that when the company needed to increase its digital capacity, investing in a second Screen press was an obvious choice.

This saw Limpet Labels install its successor, the Screen Truepress Jet L350UV+ in October 2018. The new press offered a faster production speed of 60 meters per minute, together with enhanced media handling. According to Nathan Williams, Digital Print Manager at Limpet Labels, thanks to the company’s experience with the Screen Truepress Jet L350UV and EQUIOS workflow, Limpet Labels was able to go from the installation to full production in under two weeks.

“Running both Screen presses concurrently has had an instant and substantial impact on our total capacity,” explained Nathan Williams, Digital Print Manager at Limpet Labels. “This has increased by over 60% compared to when we used the Screen Truepress Jet L350UV alongside a toner-based system. This ensures that we can get jobs out quicker than ever before and crucially allows our customers to improve their time-to-market.”

According to Williams, the company’s digital department has secured significant production efficiencies. Despite the heavy ink coverage required for many labels in the industrial, chemical and oil markets, production with the Truepress L350UV devices is more cost effective. The higher print volumes achievable has led to an increased revenue stream.

“The Screen presses ensure that we no longer need to contend with lengthy job set-ups and time-consuming maintenance. These benefits have taken our productivity to an unprecedented level. In fact, since replacing our toner-based systems with inkjet solutions, we have seen our uptime increase by 98%. This in turn has helped to secure a much healthier profit margin.”

“Beyond this, the Screen presses have proven their adaptability to short, medium and longer run jobs, offering us greater flexibility to meet fluctuating customer demands. In some cases, the two presses are equally as productive as five toner-based platforms. In terms of ROI, this is an incredible achievement and has played an integral role in digital production now accounting for 80% of our business” explained Williams.

The Truepress Jet L350UV+ includes time- and cost-saving tools such as spot colour matching, calculations of ink usage and daily print reports. It also has a large colour gamut. The addition of a chilled roller makes it possible to print on specialised heat sensitive films which has opened the door to a wide array of new label applications.

Williams concludes: “For us, Screen presses are the frontrunner in inkjet solutions for the labels market. They provide the reliability, productivity and consistency to enhance our business operation, expand our profit margin and sharpen our competitive edge.”