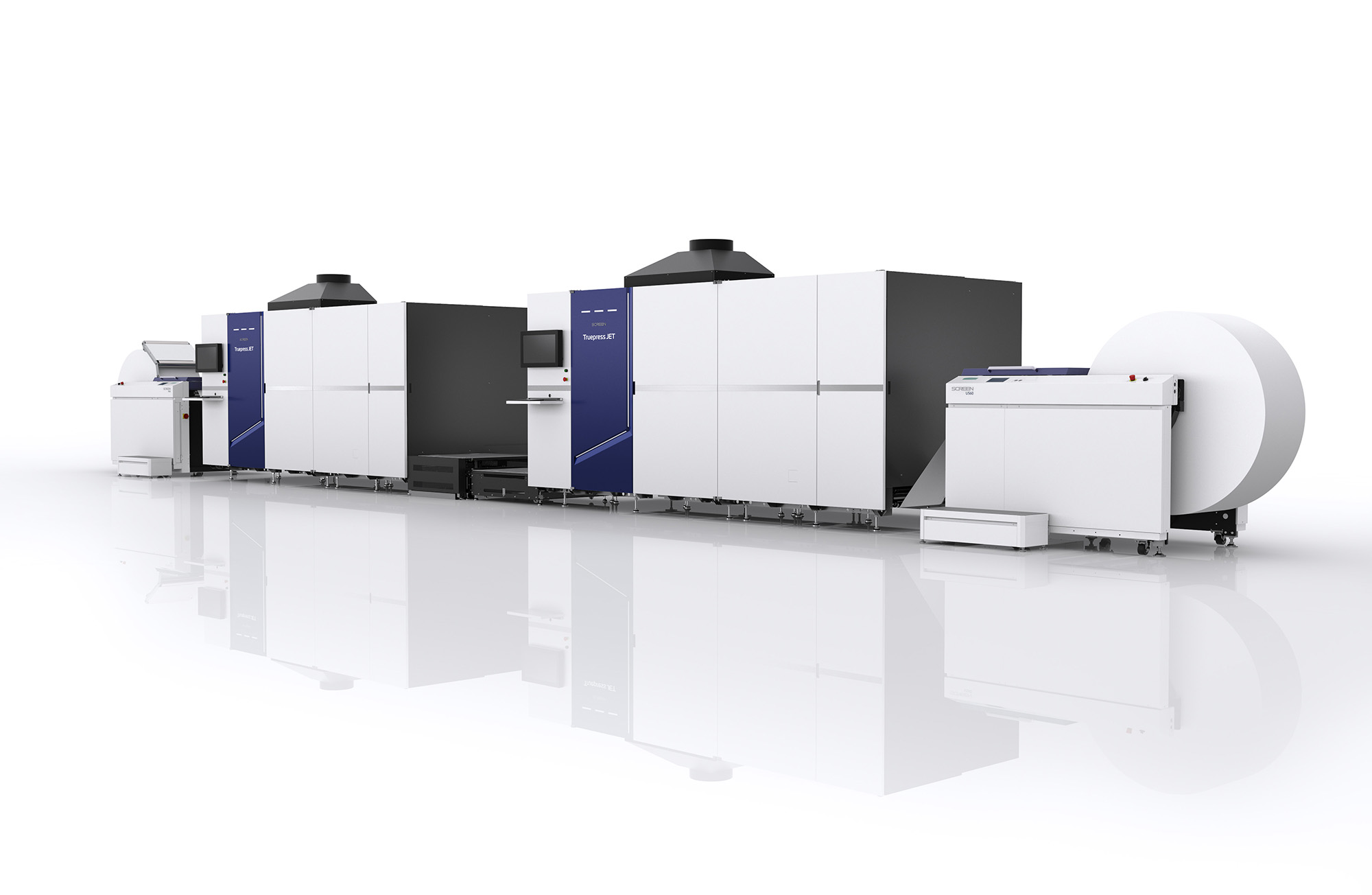

Truepress Jet L350UV+ Series UV Inkjet Label Presses

The Truepress Jet L350UV+ series is the most flexible and automated label production system in its class. Both presses support a wider range of media and applications as well as improving the industry recognised high productivity while the low migration Truepress Jet L350UV+LM system additionally expands our remit into food packaging.

For further information or to download the Truepress ink for L350 series brochure

Industry-Leading Speed Meets Unrivalled Functionality

High Speed and Quality

The Truepress Jet L350UV+ delivers industry-leading speeds for a digital label system of up to 60 meters per minute (optional setting). SCREEN’s prominent inkjet-head technology ensures both outstanding quality and throughput.

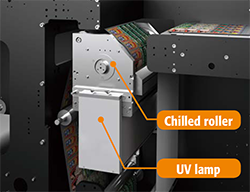

Thin Substrate Support

Thin Substrate Support

Thin substrates are particularly sensitive to heat and can deform as a result. The Truepress Jet L350UV+ is equipped with an innovative chill roller that cools these substrates and enables highly stable and fine quality. This ability opens up a wide range of new possibilities for label production.

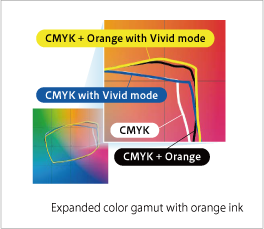

Blue and Orange Ink

Blue ink is now supported along with C, M, Y, K, white and orange inks. Corporate colours that usually require the assignment of spot colours can be reproduced with complete accuracy. Blue tones, often used in toiletry, cosmetic and body care packaging are now more vibrant and appealing than ever before.

Orange ink enables richer colour reproduction in red areas for example in fruits and other food packaging.

Expanded colour gamut with orange ink

Cutting-Edge Technologies Boost Food Label Innovation

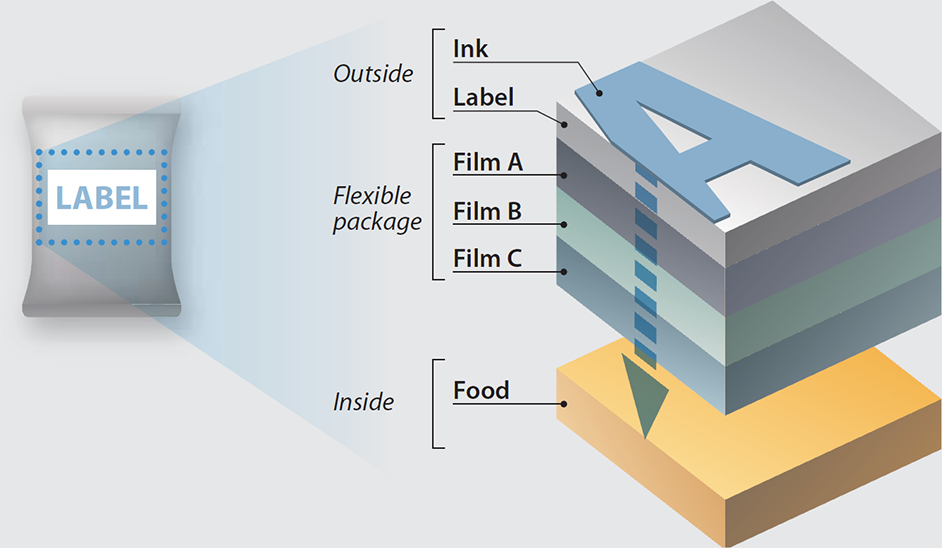

Low Migration Inks

Low Migration Inks

Labels for food packaging must satisfy strict safety standards. New low migration inks for the Truepress Jet L350UV+LM system are compliant with EuPIA Exclusion Policy for Printing Inks & Related Products, Swiss Ordinance and Nestlé Guidance. This significantly lowers the risk of ink migration and typical UV odour.

Ink Migration

This refers to the process by which some ink components pass through packaging materials and penetrate the food product.

Basic Structure

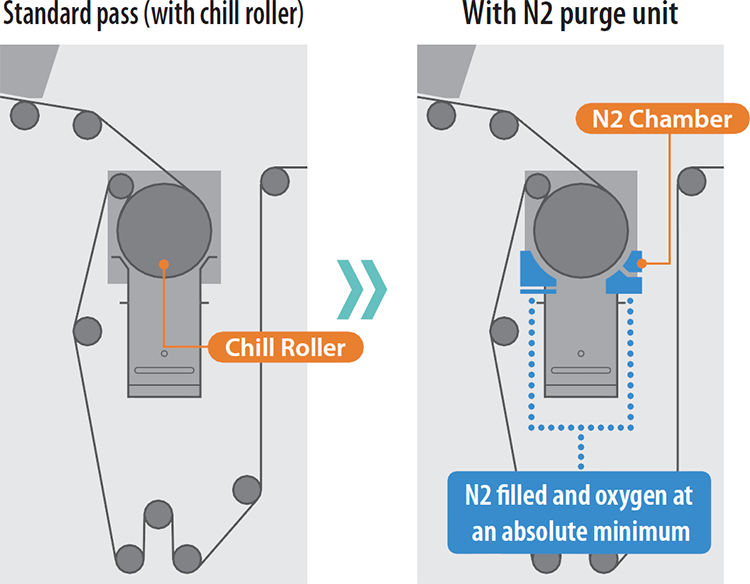

Nitrogen Purge Mechanism

Nitrogen Purge Mechanism

The Truepress Jet L350UV+LM features our newly developed nitrogen purge mechanism. UV ink curing can be inhibited by the presence of oxygen. Our innovative technology reduces its density to an absolute minimum to accelerate curing.

“Low migration” as a term has been prevalent in the printing ink market and food packaging sector for a number of years. It is a term that is intrinsically linked to food packaging compliance and the production of indirect food contact packaging, where the foreseeable use of the printed package does not result in direct contact between the foodstuff and the print.This white paper by David Pittman explains all about Low Migration and UV inkjet.

UV Curing Inks for POD Label Systems

Highly versatile, low migration Truepress inks.

Truepress ink for L350 series are specially designed for the Truepress Jet L350 series of UV inkjet label systems. These innovative inks maximize the series’ already outstanding quality, stability and compatibility with a wide range of substrates.

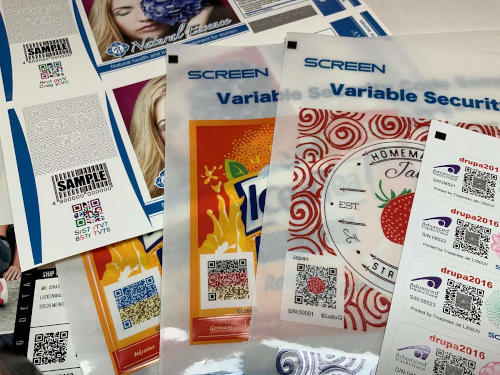

Applications

Labels

Screen delivers the UV inkjet technology that is highly prized by label printing companies looking for top-level productivity, smooth output of gradations, reproduction of wide CMYK colour gamut and single-pass versioning printing.

Paperboard (Cartons)

Printing on paperboard for primary and secondary packaging offers versatility across a number of industries. Print performance is a key object for paperboard packaging, and Screen inkjet printing systems ensure a remarkable level of performance.

Embellishment combinations

By printing under or over Kurz foil, UV inkjet samples can create catching effects.

Bottle Wrap

Bottle wraps on films with thicknesses down to 40 micron will show you the strong opacity of our whites.

Color-Logic metallic effects

For creating special effects onto metallic substrates, Equios can map a metallic separation to a white separation by using the Colour-Logic application. At the same time, it can also invert positive and negative images.

Brand protection

The standard security features like Seal Vector, variable barcoding or numbering can also be used for brand protection.

Pharmaceutical

In the pharmaceutical industry combatting counterfeiting of prescription drugs is essential. The range of security features that is included in the L350UV kit can strongly contribute to the safety of medicines within the supply chain.

Success Stories

Literature

Download Brochure

Please provide a little information about yourself before downloading the Truepress Jet L350UV+ Series brochure.

Specifications

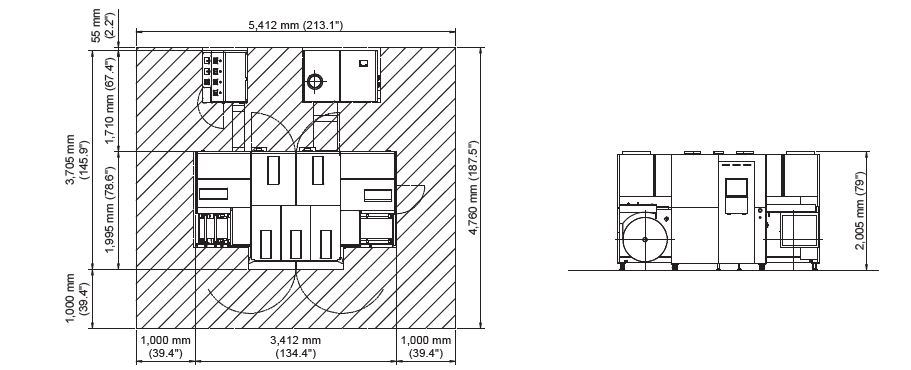

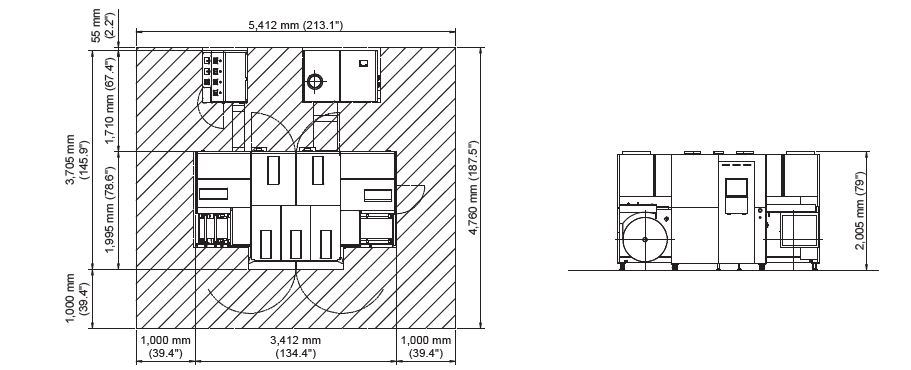

Dimensions

| Product name | Truepress Jet L350UV+LM | Truepress Jet L350UV+ |

|---|---|---|

| Printing system | Piezo single-pass printing | |

| Resolution | 600 x 600 dpi | |

| Printing speed | Maximum 19.3 m2 min at 60 m/min Maximum 19.3 m2/min at 60 m/min*1 | |

| Printing size | Width: Maximum 322 mm | |

| Repeat length: 50.8 mm to 2,400 mm | ||

| Media size | Width: 100 mm to 350 mm Roll diameter: Maximum 750 mm Weight: Maximum 120 kg |

|

| Media thickness | 0.04 to 0.35 mm*2 [when chilled roller installed] | |

| Inks | Truepress inks for L350UV+LM*3 | Truepress inks for L350UV |

| Ink tank capacity: 8 liters per color Ink bottle capacity: 4 liters per color |

||

| Output configuration | CMYK + White + Orange CMYK + White CMYK + Orange |

|

| Printheads | 4 step grayscale printheads Droplet size: Minimum 3 picoliter |

|

| Controller (bundled) | Controller for L350 | |

| RIP (bundled) | EQUIOS for L350 | |

| Options | 60 meter upgrade, web cleaner, mark sensors, corona unit, splice detection sensor, full color variable data processing | |

| MIS connection (CERM)*4 | ||

| Chilled roller and chiller*5 Nitrogen generator*5 |

Chilled roller and chiller Wrinkle reduction roller (when chilled roller not installed) |

|

| Dimensions (W x D x H) / Weight | Printer: 3,701 x 2,065 x 2,005 mm / 3,350 kg Main tank: 890 x 760 x 1,120 mm / 200 kg Power supply box: 1,327 x 878 x 1,627 mm / 580 kg |

|

| Power requirements | Three phase 200/208/220 V, 3 W, 50/60 Hz, 60 A Three phase 380/400/415 V, 4 W, 50/60 Hz, 40 A Earth leakage circuit breaker (200 mA sensed current) must be installed. |

|

| Operating environment | Required temperature and relative humidity: 15 to 25˚C / 40 to 70˚C [no condensation] Warrantied temperature and relative humidity: 18 to 24˚C / 40 to 70˚C [no condensation] Recommended elevation: less than 1,000 meters above sea level |

|

| Incidental utilities | Air-pressure utilities such as compressor Connection to exhaust duct |

|

*1. This printing speed is supported when the 60 meter option is installed.

*2. Thicknesses of 0.09 to 0.35 mm can be used with the standard specifications.

*3. The low migration (LM) inks are only available on the Truepress Jet L350UV+LM model.

*4. This option is not available in all regions.

*5. These options are required for the Truepress Jet L350UV+LM model.

| Product name | Truepress Jet L350UV+LM | Truepress Jet L350UV+ |

|---|---|---|

| Printing system | Piezo single-pass printing | |

| Resolution | 600 x 600 dpi | |

| Printing speed | Maximum 19.3 m2 min at 60 m/min Maximum 19.3 m2/min at 60 m/min*1 | |

| Printing size | Width: Maximum 322 mm | |

| Repeat length: 50.8 mm to 2,400 mm | ||

| Media size | Width: 100 mm to 350 mm Roll diameter: Maximum 750 mm Weight: Maximum 120 kg |

|

| Media thickness | 0.04 to 0.35 mm*2 [when chilled roller installed] | |

| Inks | Truepress inks for L350UV+LM*3 | Truepress inks for L350UV |

| Ink tank capacity: 8 liters per color Ink bottle capacity: 4 liters per color |

||

| Output configuration | CMYK + White + Orange CMYK + White CMYK + Orange |

|

| Printheads | 4 step grayscale printheads Droplet size: Minimum 3 picoliter |

|

| Controller (bundled) | Controller for L350 | |

| RIP (bundled) | EQUIOS for L350 | |

| Options | 60 meter upgrade, web cleaner, mark sensors, corona unit, splice detection sensor, full color variable data processing | |

| MIS connection (CERM)*4 | ||

| Chilled roller and chiller*5 Nitrogen generator*5 |

Chilled roller and chiller Wrinkle reduction roller (when chilled roller not installed) |

|

| Dimensions (W x D x H) / Weight | Printer: 3,701 x 2,065 x 2,005 mm / 3,350 kg Main tank: 890 x 760 x 1,120 mm / 200 kg Power supply box: 1,327 x 878 x 1,627 mm / 580 kg |

|

| Power requirements | Three phase 200/208/220 V, 3 W, 50/60 Hz, 60 A Three phase 380/400/415 V, 4 W, 50/60 Hz, 40 A Earth leakage circuit breaker (200 mA sensed current) must be installed. |

|

| Operating environment | Required temperature and relative humidity: 15 to 25˚C / 40 to 70˚C [no condensation] Warrantied temperature and relative humidity: 18 to 24˚C / 40 to 70˚C [no condensation] Recommended elevation: less than 1,000 meters above sea level |

|

| Incidental utilities | Air-pressure utilities such as compressor Connection to exhaust duct |

|

*1. This printing speed is supported when the 60 meter option is installed.

*2. Thicknesses of 0.09 to 0.35 mm can be used with the standard specifications.

*3. The low migration (LM) inks are only available on the Truepress Jet L350UV+LM model.

*4. This option is not available in all regions.

*5. These options are required for the Truepress Jet L350UV+LM model.