SCREEN Graphic Solutions Co., Ltd., also referred to as SCREEN GA, announces that it will take part in Horizon Smart Factory 2024, to be held by Horizon Inc. at its Biwako Plant located at 1600 Asahi, Shinasahi-cho, Takashima, Shiga, Japan, on October 2 to October 4, 2024, from 10:00 a.m. to 5:00 p.m. daily.

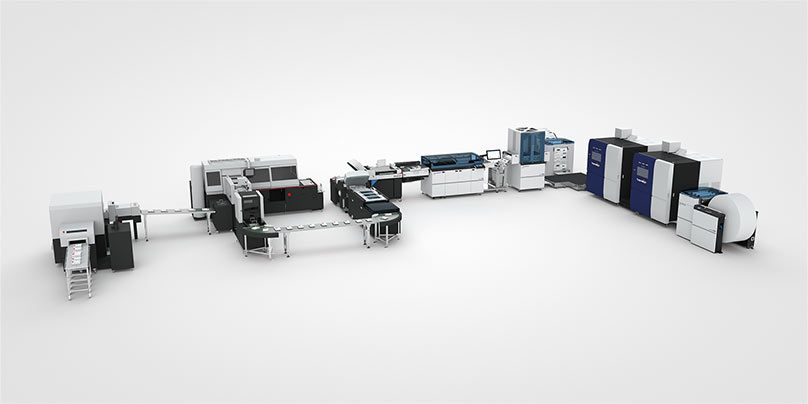

Under the theme “Lights Out: Take automation to the next level,” Horizon Smart Factory 2024 will push the boundaries of automation by addressing attendees on how they can attain autonomous printing, finishing, packaging, and other logistics with cutting-edge technology such as AGVs, robotics, and AI. The seamless integration of printers, postpress systems, and workflow systems will allow for the monitoring of each job’s production status and progress. SCREEN GA will demonstrate a completely automated perfect binding solution for publishing and commercial printing consisting of its Truepress JET 520HD mono connected to a Horizon perfect binding system.

SCREEN GA will also present a case study of a client who has installed multiple Truepress JET 520HD+ color presses at a facility where they are used in conjunction with a Horizon perfect binding system. An additional near-line configuration with other postpress systems will show attendees how these systems can be used to achieve overall success in business.

SCREEN GA will hold live demonstrations of a perfect binding, high-mix, small-lot solution using its Truepress JET 520HD mono roll-fed monochrome inkjet press connected to Horizon’s Smart Binding System for perfect binding. With the push of a button, this solution can automatically perform book-block printing, sheet cutting, gathering, binding, and three-side trimming. With the EQUIOS solution platform at its core, the solution offers job control that achieves automation for every step from order placement and receipt to finished product and shipment. This enables nonstop production of high-mix printed materials of varying finished sizes and page counts without human intervention. The solution will use Truepress ink SU. This ink, which is for uncoated paper, is a high density ink that offers low bleeding to create sharp visuals on printed samples.

SCREEN GA will also present a case study in which an overseas client realized a smart factory centered on multiple Truepress JET 520HD+ high-speed digital inkjet presses and a combination of inline and near-line postpress systems. With this example, SCREEN GA will highlight market conditions and other factors behind the decision to adopt the systems as well as the benefits typically achieved after installation.

Also covered will be details of the TRUST Network Service, which is SCREEN’s online support program that combines a range of services including accurately isolating system problems and preventive maintenance by performing remote monitoring, operational analysis, and a support information provision. Features include the Dynamic Dashboard business intelligence (BI) tool for the timely collection, display, and analysis of log data; job support tools to calculate paper and ink usage costs and manage past usage data; and health checks and advice to help prevent and swiftly resolve issues by improving the visibility of equipment conditions. We also offer Field Online Support to assist with everything from regular maintenance to dealing with defects. SCREEN Group engineers use video taken by a smartphone, a PC, or a web camera to assess the situation and provide real-time remote support.

Attendees will also be introduced to the PDFormstudio, which quickly and easily generates PDF data for variable printing on a wide range of applications including direct mail, commercial, publishing, and labels. Extremely versatile, it can be used with equipment ranging from toner to roll-fed inkjet systems. PDFormstudio also features a wealth of functions required for variable printing, including composition and aggregation tools as well as the creation of many types of barcodes and serial numbers.