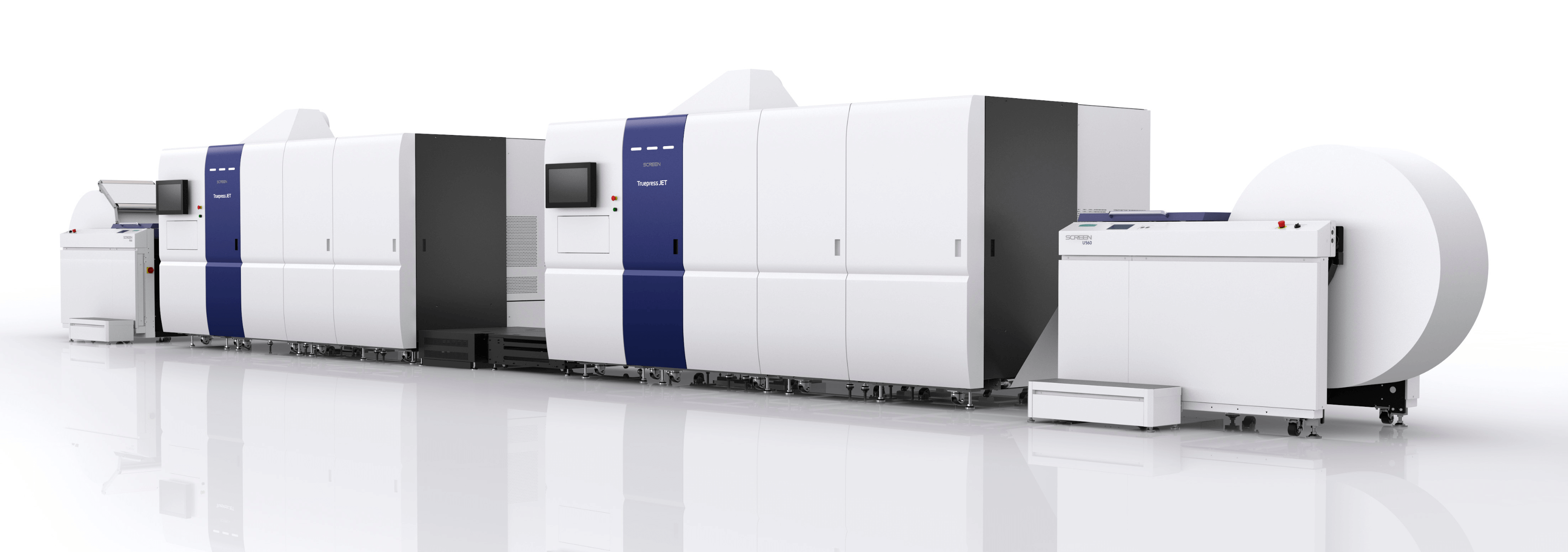

TagG Informatique of France has acquired two additional SCREEN inkjet printers to enhance speed and quality of its direct mail and transactional printing. Screen’s Truepress JET 520HD AD (Advanced Dryer) and Truepress JET 520NX have been added to an existing Screen 520HD model.

Leading French printing house TagG Informatique has acquired two Screen Truepress JET inkjet presses to increase both the speed and capacity of its production, while achieving high print quality results. The Truepress JET 520HD AD (Advanced Dryer) and Truepress JET 520NX are the second and third digital printing machines of the Screen 520HD series that TagG Informatique has acquired. The French cross-media marketing specialist leverages Screen’s innovative and high-quality inkjet technology to the fullest.

TagG CEO Hervé Lesseur: ‘better than offset’

“We chose the two Screen digital printing machines for their speed, high uptime and high print quality, which is comparable to, or even better than that of offset printing, offering TagG’s clients a competitive print-cost ratio,” says Hervé Lesseur, CEO of TagG Informatique. “Additionally, the vibrant colours and sharp details that can be printed on a wide range of paper substrates stood out,” he says.

Small droplet sizes and offset quality

What sets apart the Truepress JET 520HD series for commercial printers apart is its unique printhead technology. The press is able to accurately place down to 2-picoliter droplets — the world’s smallest level of ink droplets — precisely where the dots are required on paper as it moves through a high-speed web transfer system. Combined with the maximum printhead resolution of 1,200 dpi, the Truepress JET 520HD series can clearly image detail smaller than 0.10 of a point. The result is a sharp, eye-catching finish with no ink spread or jaggies. This way, the Truepress JET 520HD series achieves the colours, textures, details and solid ink areas expected for high-end publication and commercial work. For direct mail advertising, the enhanced design opportunities improve response rates of personalised marketing campaigns, making the Jet520HD an appealing alternative to offset/digital hybrid and toner-based production.

New Advanced ink drying

TAgG’s new Truepress JET 520HD AD features the most advanced dryer unit for the SC+ inks. It combines a constant temperature dryer with heated rollers to deliver a superior drying performance on coated or uncoated papers.

Using Screen’s unique SC+ inks, print houses’ choice of paper now includes standard offset coated stocks, removing the need for inventories of expensive inkjet-treated paper. There is no need to use a primer, thanks to SC and SC+ inks’ breakthrough absorption technology, which eliminates any pre-processing or additional primer coatings that are typically required to print to standard offset coated papers. Energy consumption is minimised and issues with heat, such as excessive drying, are avoided. Printing directly to the paper saves time and money and preserves its surface texture. This opens up a range of new possibilities and markets for inkjet printing, including commercial print, catalogues, magazines and high-end books.

CEO Hervé Lesseur adds: “In fact, we’ve achieved a noticeable improvement in colour accuracy and detail, with the new Screen presses, enhancing the overall impact of TagG’s printed materials. Their print quality is even better than offset: colours are vibrant, details are sharp.” He also adds that it was important for Screen’s SC+ ink to be fully compliant with Europe’s stringent environmental regulations. “This certification is crucial for TagG’s sustainability efforts to minimise our carbon footprint. Screen was the only manufacturer that could issue such documentation.”

TagG expects that the new Screen investments will enable business growth of between 10% to 12% in 2024.

Versatility and creativity

The Truepress JET 520HD AD, for high-qulity commercial colour, and the JET 520NX, for higher-speed transactional work, each serve different needs for TagG. The JET520HD AD can be used for direct mail, while the JET 520NX works best for transactional print jobs. TagG sees two distinct developments in these markets: direct mail is growing slightly and, at the same, the transactional market is shrinking. Lesseur says: “The decreasing volumes in the transactional market therefore require modern and cost-effective solutions. At the same time, the growing direct mail segment requires more creativity and product innovation, as well as personalised printing with print quality at least matching that of offset printing. This is what TagG has been offering for the past five years with our first Screen Truepress JET 520HD+.”

Extra printheads, closer together, improve output

The Truepress JET 520NX features a five-inch printhead module that delivers enhanced print quality of up to 600 x 900 dpi resolution and a maximum speed of up to 150 meters per minute. The gap between printheads has been reduced to just one-eighth of earlier Screen systems to deliver even higher quality and more stable printing. The Truepress JET 520NX’s printhead design efficiently handles both monochrome and full colour printing. CYM printheads can be “parked” when printing mono, to reduce ink consumption. Plus, an extra printhead can be installed adjacent to the other printheads to handle MICR and other specific function inks.

With its high quality and speed, the Truepress Jet 520NX is a superior solution for transactional printing. Fine-tuned for optimum performance, it offers a wealth of new functions to enable a wider range of applications. For instance, it supports variable printing using functional inks, such as magnetic ink for MICR.

TagG also finds ease of operation and maintenance to be valuable, as well as the relatively small footprint of the Truepress JET 520HD NX, which allows for virtually unlimited space configurations to accommodate the efficient positioning of unwind and rewind systems. Layouts can be arranged to suit installation space and orientation of the production line: I-shape, U-shape, L-shape or H-shape design. Maintenance can be performed without cutting paper, and print operation is performed effortlessly from its user-friendly touch panel. Screen’s after-sales service underpins TagG’s choice of the Japanese manufacturer’s innovative printing technology.

Screen provides exceptional ongoing customer support, with specialist teams, including here is ANZ, helping existing customers to identify optimum settings for a specific application or print job at the customer site and providing additional technical support and guidance for machine operators.