Screen, manufacturer of the Truepress Jet series of digital presses, and colour experts CGS Oris, have developed a new technology that will save time, lead to better quality printing, and meet the growing need for independent colour management solutions.

The new CxF3 (Colour Exchange Format) spot colour-matching solution – available for the CGS Oris CxF Toolbox – is a response to market demands for software that can guarantee colour consistency and enhance efficiencies for new and existing customers.

Spot colour printing is recognised as one of the best methods to capture and transmit all of the detail in colours. Unlike conventional ICC profiles, CxF data includes the spectral information of the spot colour, including halftones and transmittance. This allows for more accurate colour calculations and an optimal basis for the precise reproduction of a colour at any time.

However, generating CxF data can be a lengthy process, as it requires charts to be printed and measured for all printing conditions as well as target values to be set. Printing methods have expanded with the uptake of digital printers and hybrid solutions. This has led to a need for independent colour management solutions that can guarantee consistent colour reproduction – even when switching from a conventional printing press to a digital output.

Screen Australia Managing Director Peter Scott says: “Screen and CGS Oris have co-operated for a while on various aspects of colour management. This new CxF spot colour initiative is a great boost for the label and packaging industry in particular, as spot colours are often a contentious issue between brand owners and print service providers. Mixing and applying special colours is time-consuming and expensive, now 100% accurate spot colours can be generated for our L350UV SAI label and packaging presses, quickly, easily and without high-level colour management knowledge.”

Perfect colours, easily achieved

To meet these market demands, Screen and Germany-based CGS-Oris, developed a technology that predicts halftones from limited colorimetric data by using a proprietary algorithm. This automatically generates complete CxF data, saving significant amounts of time. This has made it easier for new users to adopt CxF, as well as improving efficiencies for existing users.

More companies can now benefit from CxF’s many advantages. These include a more holistic representation of a colour, the best fundamentals for reproducing colours on different printing presses, and flexible and independent colour management, regardless of the operator’s skills.The new technology is available from Screen for the CGS Oris CxF Toolbox – the software solution used to capture, store and edit CxF data, in a fast, reliable and safe way.

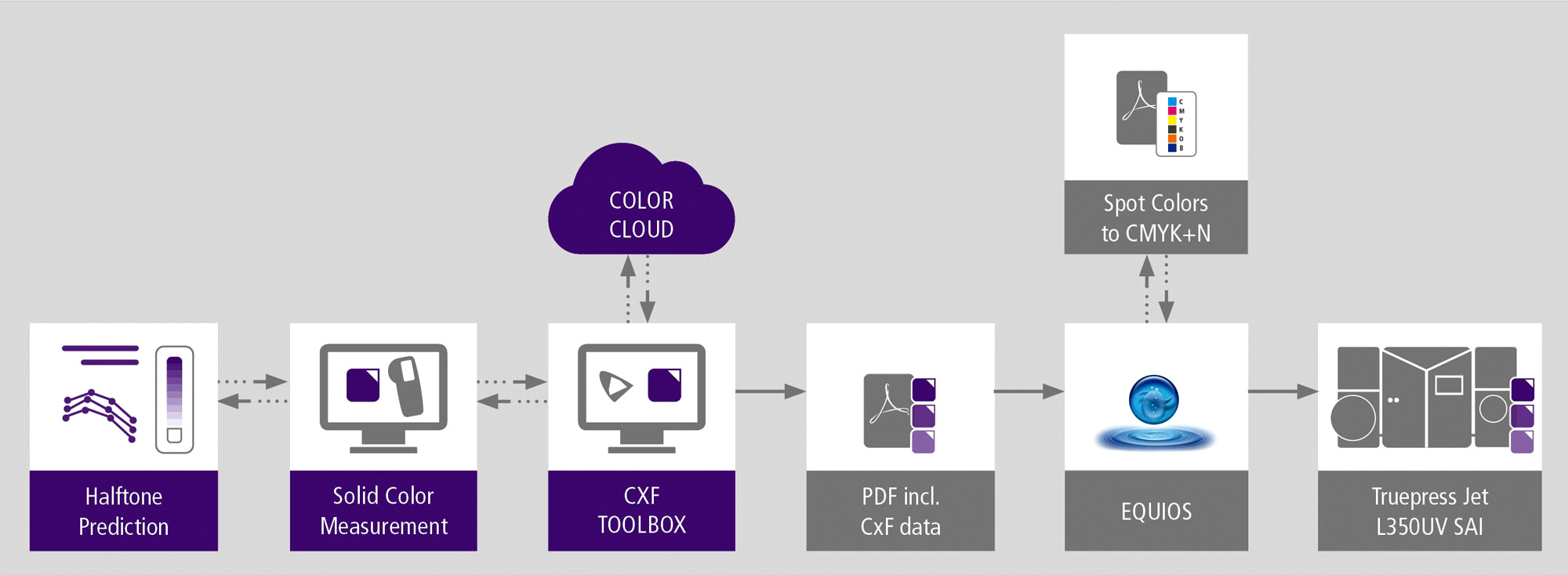

The set-up is simple, with the user needing only to present output colour charts under certain printing conditions and put the colour measurement data into the CxF Toolbox. Once the set-up is ready, the system is able to automatically generate CxF data of particular spot colours or entire libraries, without requiring any colour expertise. The generated CxF data can easily be embedded in PDF files to be used for a pre-press process.

The Cloud does the work

The CxF Toolbox is seamlessly connected to the CGS Oris Color Cloud, the cloud solution provided by CGS Oris to communicate all stored CxF data to the entire supply chain. It guarantees authorised users around the world access to complete and up-to-date colour data – at any time. Even large amounts of a brand’s CxF data can be organised and communicated with the CxF Toolbox and the Color Cloud, including brand owners with collections of more than 200 brands.

Additionally, the Color Cloud can be used with the entire CGS Oris Software Suite, like Press Matcher, X Gamutetc, and can be connected to other workflows, including Screen’s Equios, and DFEs that work with CxF data. Screen’s newly – developed UV inkjet printer for labels,Truepress Jet L350UV SAI, processes PDFs with embedded CxF data, and is able to separate them into up to six colours of CMYK + OB. In combination with CGS Oris’s multi-colour separation technology, Screen’s inkjet technology enables the accurate reproduction of spot colours, even without the use of special colour inks.